Mill Hill Cottage Plumbing & Heating Ltd

(Previously

Heating Innovations)

|

|

|

Dry Well Thermostat Introduction

(also known as the Pipe Stat, Aquastat or

Immersion Pocket Thermostat).

A dry well thermostat is supplied with the H2 panel,

it is a very important link in the control system indicating the status of

the solid fuel boiler, either the boiler is up to working temperature (58°C)

or it is not, it controls the following functions

| When the solid fuel boiler is not in operation it

is isolated from the rest of the system, thus preventing the automatic

boiler from wastefully heating the solid fuel boiler. |

| When the solid fuel boiler is first lit, or in

slumber mode it is prevented from sharing its output with the rest off

the system until it is up to working temperature, this keeps

condensation and resulting corrosion in the fire box to an absolute

minimum, extending the boiler life. |

| When the information that the

solid fuel boiler is up working temperature is relayed to the control

system, if the automatic boiler is also operating at the same time,

the system will go into link up. |

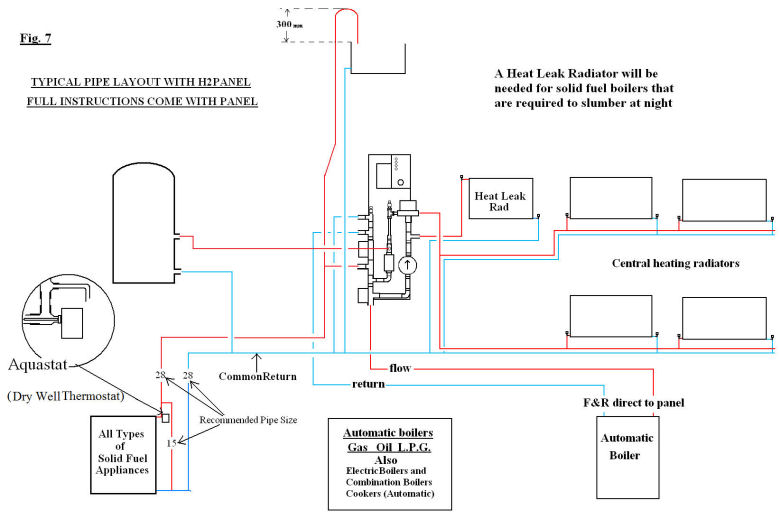

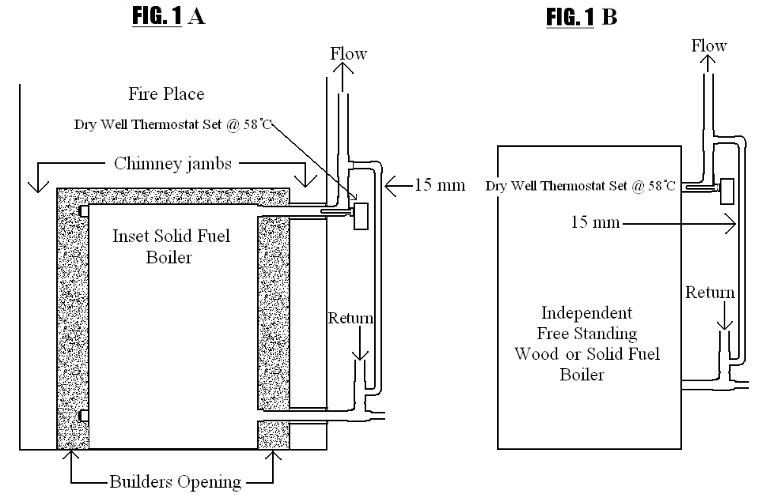

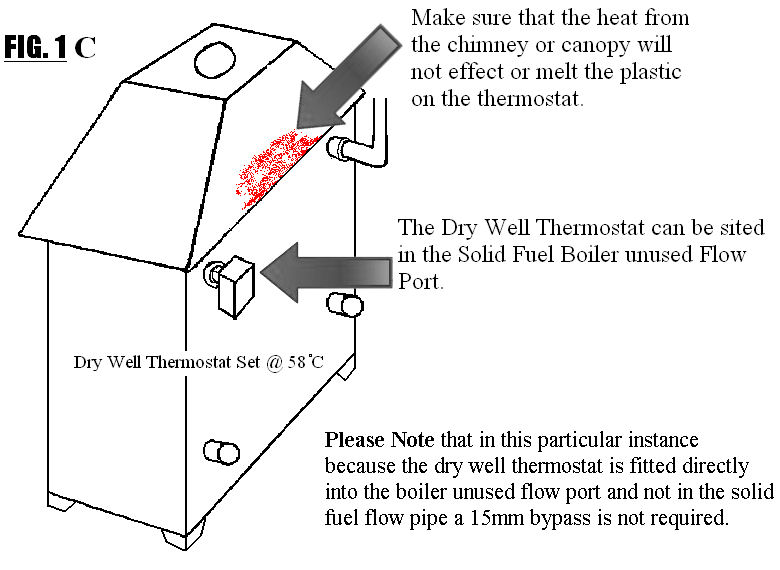

Positioning the Dry Well Thermostat

In order that the dry well thermostat carry out its

purpose efficiently it is crucial that it is correctly sited and installed on or near the solid fuel

appliance, see figures 7, 1A, 1B, & 1C below

Dry Well Thermostat fitted close to the boiler in the solid

fuel flow pipe

Dry Well Thermostat fitted in solid fuel boiler unused flow

pipe

|

| Dry Well Thermostat Installation |

Contents of the dry well thermostat box

| dry well thermostat |

| dial |

| PVC grommet and alternative thermoplastic fixing for the

wiring. |

The dry well pocket has a 1/2 inch BSP male thread so

I will need a female fitting to screw it into.

|

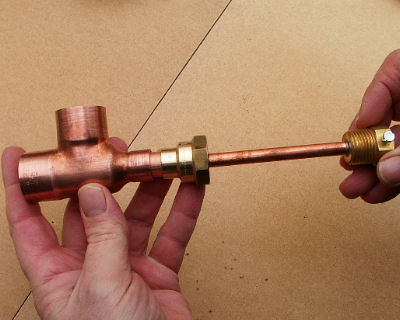

To accommodate the dry well pocket into the solid fuel flow I am going

to use a 28x15x28 tee, one end reduced, a standard 15mmx1/2 inch straight

female connector and a short piece of 15 mm pipe (length of the pipe

will vary depending on what type and even brand of fitting you are using)

.

I could have used a

male connector and gone straight into the tee, but did not have one

available

|

Introduce the pipe to the connector, and....

|

the pipe to the fitting.

|

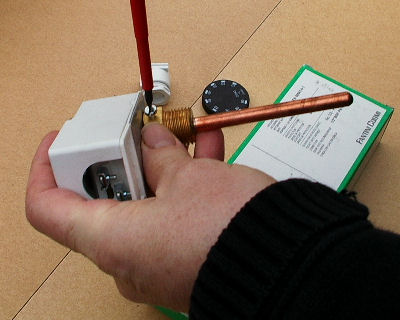

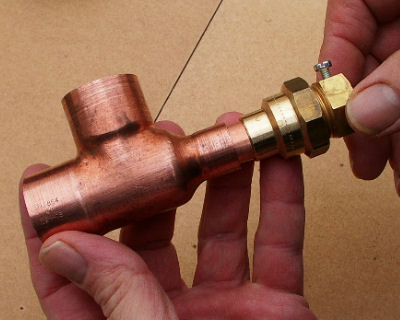

Loosen the dry well pocket retaining screw and.....

|

Carefully slide the dry well pocket off the copper bulb sensing

element. Please handle with care.

|

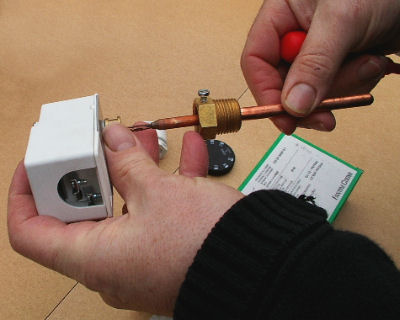

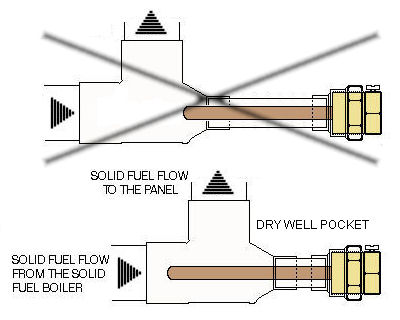

To ensure the thermostat is as responsive as possible it is important

that the dry well pocket is right into the solid fuel flow, as in the

diagram above. Before I start any soldering I check it is sitting

correctly by......

|

sliding the dry well pocket into the fitting and...

|

screwing the dry well pocket into the 1/2 inch female connector. If the

well is not right into the flow shorten the 15mm pipe until it is.

|

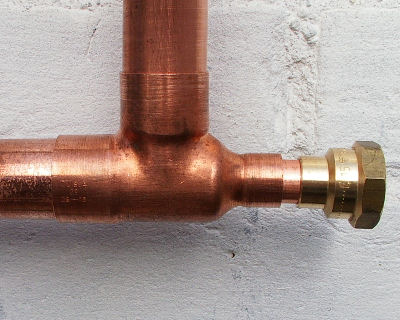

When pipe length is adjusted correctly, unscrew the dry well pocket and

|

flux and solder joints.

|

Wrap the 1/2 inch thread of the dry well pocket with sealing tape and

screw into the female fitting

|

tighten with a spanner

|

Remove dry well thermostat thermoplastic cover retaining screw

|

remove thermoplastic cover

|

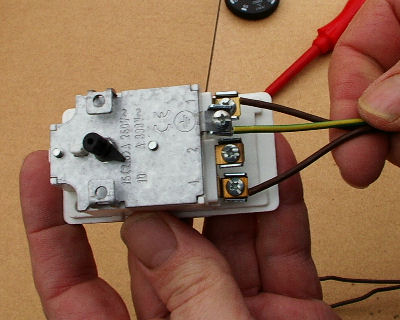

Terminals are clearly labelled, when temperature set is satisfied

the snap action microswitch makes terminals 1-4

1. Common (C)

2. Break on temperature rise (NC)

4 Make on temperature rise (NO) |

Slide the wire through PVC grommet and connect two wires to terminals 1

and 4 earth wire and to earth terminal. Please note terminal 2 is not

used.

|

Tighten terminal screws and slide grommet up

|

Slide grommet into thermoplastic cover and refit cover to thermostat

|

Carefully slide

copper bulb sensing element into the dry well pocket

|

When thermostat is completely home tighten the dry well pocket

retaining screw and.......

|

push the dial on.

|

Set dial to 58 degrees Celsius

|

This end is complete.

|

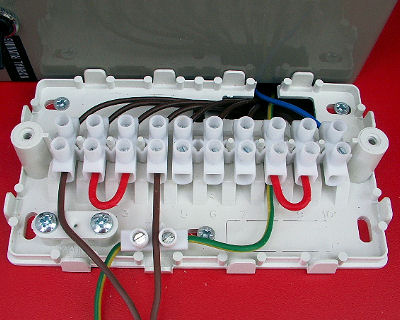

Back to the H2 panel, remove Honeywell junction box cover

|

Terminals are labelled 1 to 10 from the left in this photo, it will be

from top to bottom for you

a) connect earth wire to single loose earth terminal.

b) connect terminal 1 on the thermostat to terminal 1 on the H2 panel

junction box and

c) connect terminal 4 on the thermostat to terminal 4 on the H2 panel

junction box

|

|

Contact Mill

Cottage Plumbing & Heating Ltd

Technical Support and

Sales

Telephone 01354

653854 |